Tailor Made Planetary Mixers

TRAXIT Planetary Mixer provides the modern industry with unlimited possibilities of application for the processing of fully homogenous mixes of medium to high viscosity pastes.

TRAXIT Planetary Mixer provides the modern industry with unlimited possibilities of application for the processing of fully homogenous mixes of medium to high viscosity pastes.

Application:

Good homogenity with high efficiency in processing viscous products can be achieved with TRAXIT Planetary Mixers.A partial list of actual application is given below:

Adhesives:

Epoxies,Polyurethanes,Polysulphides,Rubber,Cement,Silicones,Hot melts etc.

Chemicals:Abrasives,Battery pastes,Brake linings,Ceramics,Gasketing materials,lubricant pastes,tungsten Carbided Powders,Rocket Propellants etc.

Coatings:Artist colors,Flush colors,Paints,Printing inks etc.

Foods:Confectionary products,cheeses,Food colours,seafood mixtures,Sausage casing etc.

Pharmaceuticals:Dental products,Granulations,Toothpastes,Gelatin compounds etc.

Plastics:Polyester coatings,Plastisols,Powder Coatings etc.

OPERATING PRINCIPLE

In principal the mixer consists of a set of mixing elements operating in a vertical cylindrical container . The mixing elements rotate around their own axis and also traverse along the wall of the container thereby performing a planetary motion and hence the name

CONSTRUCTION & OPERATION :

Traxit : planetary mixer can depending upon the size and the consistency of the product being processed , be provided with – one or two mixing elements . Apart from the mixing elements a scraper is also provided to enable the material sticking to the vessel clean to enable better heat transfer in case the product being processed is heated or cooled .As a result of the design of the mixing elements and the operating in relatively short mixing times and with less mixing power

TRAXIT:

Planetary mixers are supplied complete with electrical controls required for safe operation of the equipments and for safety of the operating personnel traxit planetary mixers can be provided right from laboratory models of 10 ltrs ., to production equipment of 1000 ltrs

DISTINCT ADVANTAGES:

Planetary mixers have distinct advantages over other mixers which can be highlighted as :

• The mixing zone if free from any seal

• The mixing elements can be raised to clear the container and , the container which is mounted on castors , can be moved out off or into the mixing zone . Thus . change – cans can be used . this feature is especially useful when different products are to be processed in the same equipment , as , the container and the mixing elements can be approached easily and cleaned thoroughly there by eliminating inter – batch contamination .

• Mixing elements can also be changed easily depending upon the application

TRAXIT : planetary mixers can be provide with appropriate features as highlighted below to give optimum performance clients requirements

» Material of construction : Generally the contact parts are made of stainless steel to ALSL -304 . however any other fabricate –able material can also be provide as dictated by the product being processed

» Mixing Elements , depending on the process requirement different types of mixing elements can be provide , though the pitched paddle is the standard

» Operating conditions, the container Can be provided with a jacket to heat or cool the product designed to operate under standard atmospheric under vacuum or positive internal pressure , as required by the process

» Electricals , if the process demands . flame proof electrical (Motor) can be provided,in which case the electrical control panel is expected to be mounted out side the flame proof area and will be of non flame proof construction,designed for remote operation by means of flame proof push button stations mounted on the equipments.The inter-connecting wiring has to be carried out at site,for which,the necessary electrical circuitry will be provided.

Our Products

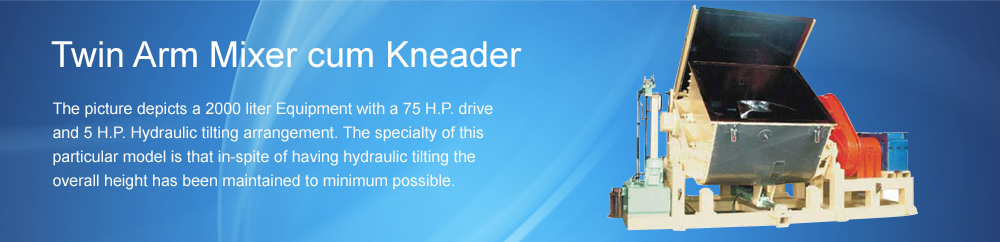

- Twin Arm Mixer cum Kneader

- Tailor Made Planetary Mixers

- Contra Mixer

- Rubber Cutter Dissolver

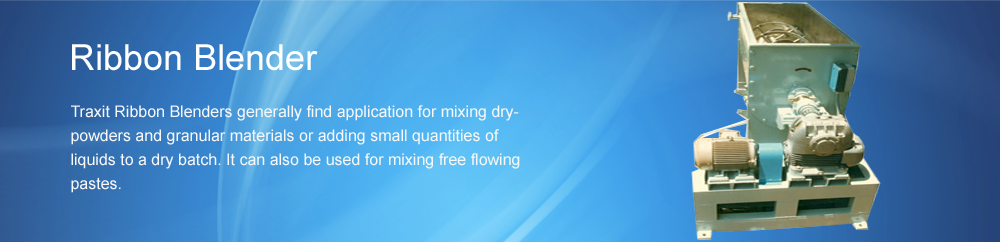

- Ribbon Blender

- Ploughshare Mixers

- "V" Blender

- Vertical Rotary Air Lock

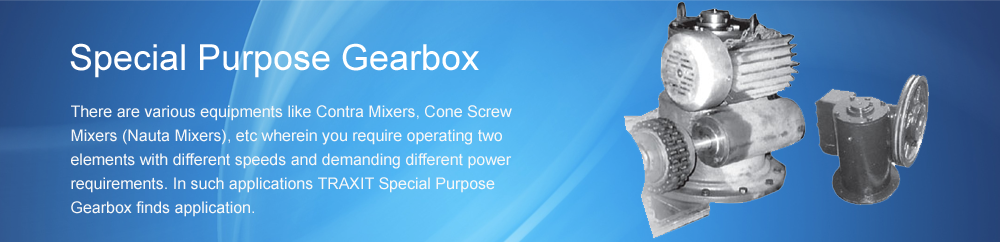

- Special Purpose Gearbox

- TEPL Lube Applicator

- Vertical Ribbon Blender

- Continuous Kneader

- Vacuum Double Planetary Mixer

- Schredder

- Disperser

- Cone Screw Mixer

- MFB Mixer